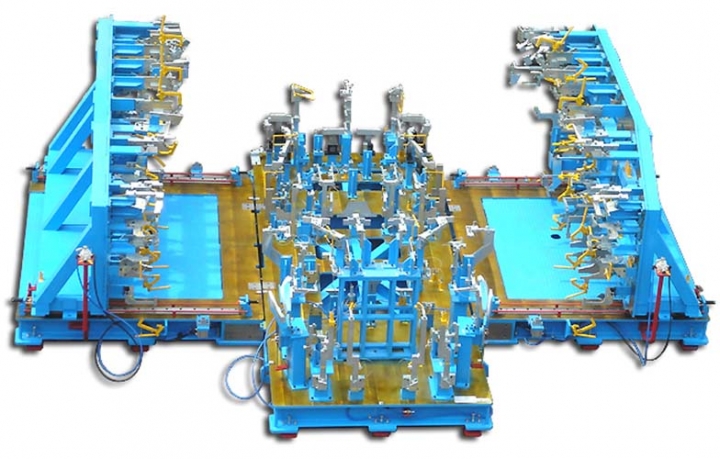

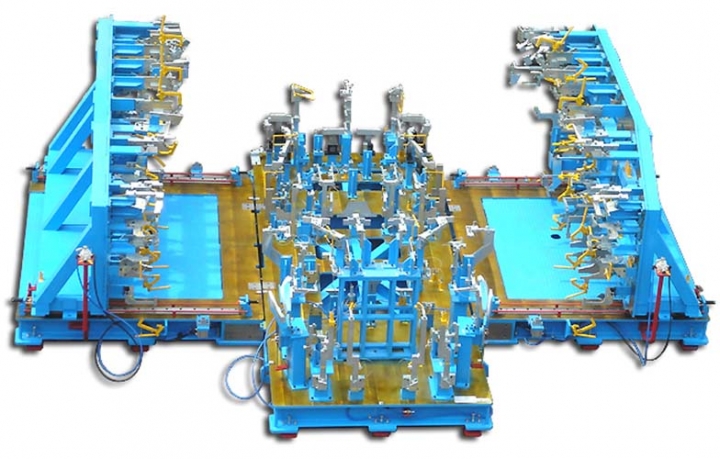

The features of Custom Automobile Checking Fixtures:

1. Specific Design: Custom automobile checking fixtures are designed and tailored specifically for the automobile industry. They are customized to fit the unique dimensions, shape, and features of automobile components, ensuring accurate and reliable measurements. 2. Component Verification: Checking Fixture is used to verify the conformity and accuracy of automobile components during the manufacturing process. They ensure that each component meets the required specifications and tolerances, preventing defects and ensuring quality control. 3. Multifunctional: Custom automobile checking fixtures are versatile and can be designed to measure multiple features or dimensions of automobile components. They can accommodate various inspection points, such as hole locations, surface profiles, mating surfaces, and geometric dimensions. 4. Durability: Checking fixtures for automobiles are built to withstand the rigors of the manufacturing environment. They are constructed from high-quality materials that are durable and resistant to wear and tear, ensuring prolonged use and maintaining accuracy over time. 5. Stability and Precision: Automobile checking fixtures provide stability and precision during the measurement process. They securely hold the component in place, reducing the risk of measurement errors caused by movement or vibration. 6. Compatibility: Custom automobile checking fixtures can be designed to integrate with other measurement tools or equipment used in the automotive industry. This allows for seamless data transfer and analysis, ensuring efficient and accurate inspections. 7. Ergonomics: Checking fixtures for automobile components are often designed with ergonomic considerations. This ensures ease of use and accessibility for operators, allowing for efficient and comfortable inspection processes. 8. Quick Set-Up: Custom automobile checking fixtures are designed for quick and efficient set-up, reducing downtime in the production line. They are equipped with features like quick-release mechanisms and adjustable components, allowing for easy and rapid assembly. 9. Traceability: Checking fixtures used in automobile manufacturing often include provisions for traceability and documentation. They can be designed with part numbers, serial numbers, and other identification features, ensuring proper tracking and recording of inspection results. 10. Quality Control: Custom automobile checking fixtures are an integral part of quality control in the automotive industry. They help manufacturers ensure that all components meet the required specifications, tolerances, and quality standards, enabling the production of high-quality automobiles. In summary, custom Stainless Steel Cnc Machining Part automobile checking fixtures offer specific design for automobiles, component verification, versatility, durability, stability, precision, compatibility with other measurement tools, ergonomic design, quick set-up, traceability, and quality control. These features make them essential tools in the automotive manufacturing process, enabling accurate and efficient inspection of automobile components.